1, Machine's main features

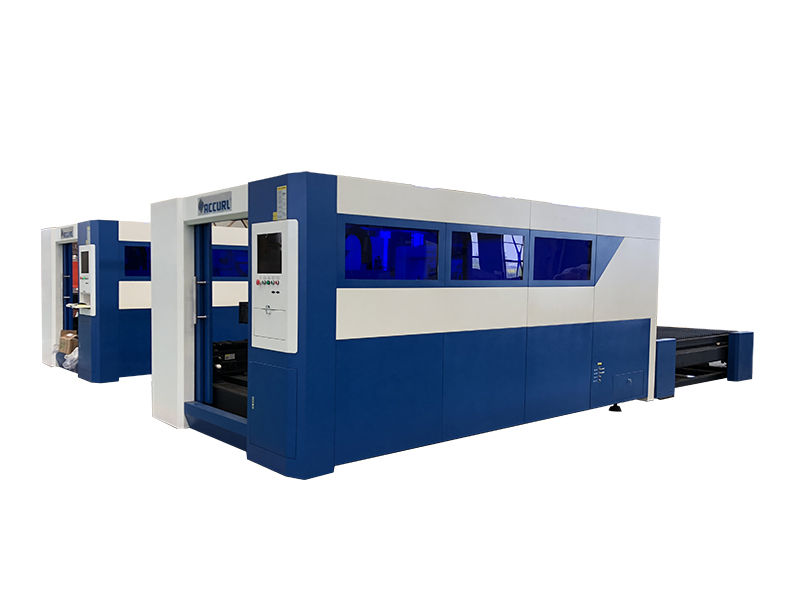

Machine consists of machine host, computer control systems, fiber laser cutting head, chillers, auxiliary decency components.

Machine gantry structure, using Japan YASKAWA servo motors drive rack and pinion feed, high precision and fast speed, dual-drive gear and rack transmission instead of the traditional ball screw transmission which makes the machine empty moving speed up to 40-50meters/Min.

Bed gantry, machine welded structure, aging treatment after annealing, roughing, finishing, can completely eliminate stress welding and machining, rigid, high precision, can be maintained long-term use not deformed( at least 20 years).

X, Y axes are imported Japan YASKAWA high precision servo motors, high speed, high torque, and high inertia, stable and durable. Ensure the machine's high speed, high precision and acceleration.

Special cutting software, integration of a number of laser cutting control specific modules, powerful, good man-machine interface, easy operation. The cutting head selection of Swiss brand high quality Ray Tools brand fiber laser cutting head as well as dedicated capacitive sensing, high precision sensor, responsive, performance of the most stable and reliable.

Control systems; Use of computer-controlled electric table translation is complete work piece cutting and so on. Cutting can be done in any graphic editor and sports plane.

Machine main parts adopt the Europe, Japan and Taiwan famous brand, its China's price but European machine quality.

2, Machine main technical advantage

2.1 Machine tool

This Machine bed with gantry design, machine welded structure, beams constructed of cast aluminum after annealing aging treatment, and then roughing, finishing, can completely eliminate stress welding and machining, rigidity, precision high, can be maintained long-term use at least 20 years not deformed.

Machine Beam gantry with the overall Aluminium casting parts which can reduce weight beams, to ensure good stability, high-speed operation can meet the machine.

Machine weighing 4 tons, variable analysis technique using structural dynamic design principle and finite element method designed machine base has excellent static and dynamic performance.

| تکنیکی پیرامیٹرز | |||

| Floor area | About 4650 * 2520mm (excluding loading and unloading area) | ||

| Allow material Maximum cutting area | 1500 * 3000 ملی میٹر۔ | ||

| Machine Gross weight | 4000KG | ||

| Power supply requirements | 380V/ 50Hz | کل طاقت | 20KW |

| Environmental requirements | Temperature range: 10-35 ºC Humidity range: 40-85% 1, 000 meters above sea level, the use of environment non-flammable, explosive, magnetic, strong earthquakes | ||

| Equipment moving system parameters | |||

| Cutting speed, acceleration | 0-50m / منٹ 0-3000mm/s2 | ||

| Air-way speed, acceleration | 0-50m / منٹ | ||

| درستگی پوزیشننگ | <0.03mm/m | ||

| ڈرائیو سسٹم | Adopt Japan YASKAWA servo motors drive | ||

| ٹرانسمیشن | All use high precision helical rack and pinion | ||

| Feedback and transport control systems | Dedicated transport and control system | ||

| Ventilation system | Fixed lower ventilation | ||

| Workbench Type | Rack Workbench | ||

| Circuit and protection system | Standard Design | ||

Our fibe laser cutting machine main laser cutting functions

| نہیں. | فنکشن | تفصیل |

| 1 | Height Follow-Up | Torch Move Up And Down According To Plate Height |

| 2 | Power Control | Laser Power Control According To Slope |

| 3 | Reverse Function | Reverse To Execute NC Program |

| 4 | Breakpoint Return | Return To Breakpoint After Recovery |

| 5 | Multi Piercing | Pulse, Blasting, Progress, High-Speed |

| 6 | Lead Line | Set Lead Line Parameter |

| 7 | Auto Edge-Finding | Find Cutting Piece Coordinate Automatically |

| 8 | Leapforg Function | Leapforg To Improve Cutting Efficiency |

| 9 | Common Line | Common Line To Improve Cutting Efficiency |

| 10 | Marking Function | Mark Any Shape On Plate |

Laser cutting thickness and speed for reference ( based on the laser power 800W, other laser power the data will be little difference)

| مٹیریل۔ | موٹائی (ملی میٹر) | Recommend Cutting Speed(mm/min) | Max Cutting Speed(mm/min) | Power (W) | Cutting Gas | گیس پریشر (kPa) | Focus (mm) | Nozzle Model | Defocusing (mm) |

| SS | 1 | 10000 | 12000 | 700 | این 2 | 8 | 0 | 1.5 | 0.7 |

| SS | 1.5 | 5000 | 5500 | 700 | این 2 | 8 | 0.7 | ||

| SS | 2 | 2500 | 3000 | 700 | این 2 | 9 | -1 | 1.5 | 0.7 |

| SS | 3 | 1500 | 1800 | 700 | این 2 | 9 | -2 | 2 | 0.7 |

| SS | 4 | 1200 | 1400 | 700 | این 2 | 9 | -2 | 2 | 0.7 |

| SS | 5 | 600 | 680 | 700 | این 2 | 10 | -3 | 2 | 0.7 |

| MS | 0.5 | 9000 | 10000 | 700 | O2 | 1 | 2 | 1.2 | 0.7 |

| MS | 1 | 8000 | 9000 | 700 | O2 | 1 | 2 | 1.2 | 0.7 |

| MS | 1.5 | 6200 | 7000 | 700 | O2 | 1.4 | 2 | 1.2 | 0.7 |

| MS | 2 | 3500 | 4000 | 700 | O2 | 1.4 | 2 | 1.2 | 0.7 |

| MS | 3 | 3000 | 3600 | 700 | O2 | 1.2 | 2 | 1.2 | 0.7 |

| MS | 4 | 1800 | 2000 | 700 | O2 | 1.2 | 2 | 1.2 | 0.7 |

| MS | 5 | 1500 | 1800 | 700 | O2 | 0.6 | 2 | 1.2 | 0.7 |

| MS | 6 | 1100 | 1200 | 700 | O2 | 0.8 | 2 | 1.5 | 0.7 |

| MS | 8 | 900 | 1000 | 700 | O2 | 0.6 | 2 | 1.5 | 0.7 |

| MS | 10 | 700 | 800 | 700 | O2 | 0.7 | 2.5 | 1.5 | 0.7 |

Machine Rough Consumption costs ( based on laser power 800W machine, the other laser power the data will be little difference)

A> Total Power Consumption

| Machine Part | طاقت (kW) | طاقت کا استعمال (kW/Hour) | نوٹ |

| لیزر جنریٹر | 5.8 | <=21 | Due to the power price is different in every country, so I can only give power consumption, couldn't give total price cost |

| CNC Table | 5.8 | ||

| Cooling Unit | 5 | ||

| Extraction Filter | 4.4 |

B> Gas Consumption

| گیس۔ | Consumption (Minute/Bottle) | نوٹ | نوٹ |

| O2 | 60 | Calculated based on 1mm MS Plate | Due to the gas price is different in every country, so I can only give gas consumption, couldn't give total price cost |

| این 2 | 15 | Calculated based on 1mm SS Plate |

C> Consumables parts

| Consumables | Life(Hour) | Unit Price (USD/Piece) | Total Cost (USD/Hour) | نوٹ |

| حفاظتی آئینہ۔ | >=240 | 43 | 0.18 | If working environment is good, then consumables' Life will be longer |

| نوزل۔ | >=600 | 21.4 | 0.04 | |

| Ceramic Ring | >=1500 | 108 | 0.07 | |

| Total | 0.29 USD/Hour | |||

Total Consumption

| آئٹم | طاقت Consumption | Gas Consumption (USD/Hour) | Consumables | نوٹ |

| O2 | <=21 kW/Hour | 60 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm MS Plate |

| این 2 | <=21kW/Hour | 15 (Minute/Bottle) | 0.29 USD/Hour | Calculated based on 1mm SS Plate |

لیزر کاٹنے والا سافٹ ویئر (خود کار طریقے سے گھوںسلا کرنے والا سافٹ ویئر) تعارف۔

"لیزر کٹنگ ڈیزائن سوفٹویئر" فلیٹ کاٹنے والے ڈیزائن سافٹ ویئر کے لئے مرتب کیا گیا ہے ، جس کا بنیادی ہدف تصویری پروسیسنگ ، پیرامیٹر کی ترتیبات ، کسٹم کاٹنے کے عمل کو ایڈیٹر ، نقلیہ سازی ، اور سست ترتیب دینا اور پروسیسنگ فراہم کرنا ہے

یہ درج ذیل ڈیٹا ان پٹ وضع کی حمایت کرتا ہے۔

6.1) After time support DXF, PLT and other graphical data formats accepted international standard G code Mater Cam, Type3, Wentai software generated DXF import graphics, text outlines AutoCAD direct extraction system transferred graphic image data, you can edit the layout (like zoom, rotate, align, copy, combination, smooth, merging operation) of the imported data to automatically check the legality, such as: Closed, overlapping, self-intersecting, distance between the detection of graphics, the cutting type (female cut, Yang cut), and external relations, interference relationship, automatic calculation of introducing cutting patterns, export line.

6.2) Process according to need, can be freely modified start position and graphics processing direction, while the system dynamically adjust the introduction of lead position, file import always automatically optimize the processing sequence, but also can be manually adjusted to reduce the processing time and improve processing efficiency select the graphic output, support anywhere in the processing of local data, particularly useful for feeding, while you can use the crop function, a graphics processing locally unique breakpoint, the process can go forward along the track, rewind, flexibility encountered each process case, according to the graphic processing, raw material size, automatic nesting